Ionizer Disinfection and sterilisation devices

Ionizer Disinfection and sterilisation devices

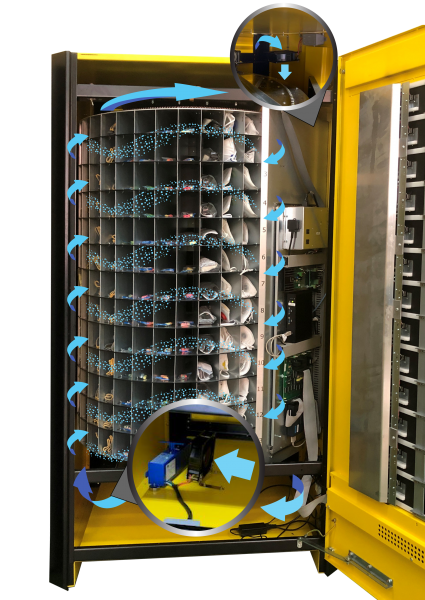

Ionization technology is new system for cleaning the machine interior from viruses, fungi and allergens. The maintenance-free ionization system of air particles allows for sterilization of products in the machine.

Product description

This system uses needle bipolar air ionization. Ions are ejected from carbon fibre brushes and distributed through the ventilation system. Together with the ionizer, a fan system is installed, which ensures accurate and efficient circulation of the cleaned air. By ensuring proper air circulation inside the machine, all articles inside the machine are disinfected and free of viruses or pathogens. The air ionizer also ensures good air quality and freshness. It removes volatile organic compounds and gets rid of odour and bad smells. The use of the entire air circulation system allows to process up to 8100 m3 of flowing air per hour of operation. The ionizer is certified by the Polish National Institute of Public Health.

SYSTEM EFFICIENCY

The use of ionizer in PSPG vending machines allows to fight bacteria, fungi, moulds and viruses that can be found on the attics inside. Laboratory tests show that it is effective against various pathogens. We can include them among others:

- Tuberculosis

- Clostridium difficile

- Norovirus

- MRSA

- E.coli

- Legionella

- Mould spores

- SARS-CoV2

SARS-CoV2

Laboratory tests confirm the effectiveness of the device in fighting COVID-19 virus. Hydrolysis by means of positively charged hydrogen ions binding to SARS-CoV-2 virus peplomers may cause 99. 4 % or the virus particles to be inactivated on the surface within 30 minutes. Studies have shown that bipolar needle ionization has the ability to neutralize pathogens, namely SARS-CoV-2, on a static surface. This allows you to maintain the disinfected interior of PSPG vending machines and articles inside it.

AUTOMATIC SELFCLEANING

The ionization system is powered by direct current, so that the carbon fibers are charged with high voltage and attract dust. This ensures that each set of brushes remains the same polarity. In AC systems, on the other hand, the dust particles are attracted in one cycle and then repelled in another. Using the same polarity allows to keep dust particles on the brushes. The manufacturer has developed an automatic brush cleaning system for dust removal from the tips. This solution allows for maintenance-free ionizer operation. Over time and hundreds of self-cleaning cycles, carbon fibre brushes may wear due to mechanical friction and need to be replaced.

English

English  Polski

Polski Français

Français