Helga 6 COMPACT Clothes collection and distribution

Helga 6 COMPACT Clothes collection and distribution

Helga 6 the automatic system of clothes distribution and collection

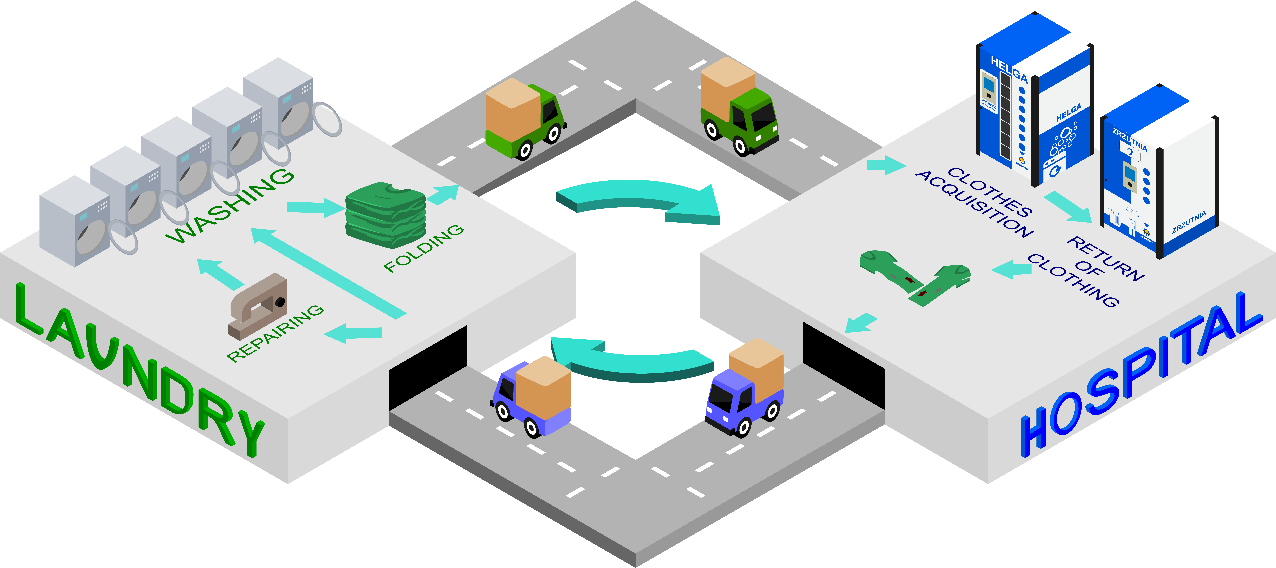

The integrated system of clothes distribution and collection It contains management software of the whole cycle of clothes circulation. Our product control and management covers all stages: distribution, collection, transportation from the customer, washing, potential repair, transportation to the customer and the loading of clothes ready to be taken into the distributing machines. Our machines recognize clothes by HF and UHF tags system or by means of barcode scanners.

Technical parameters

| Size of the machine | 201x99x90cm |

| Number of locations | 395kg |

| Size of locations | 216 |

| The weight of the machine | 6×26 cm |

Product description

We are presenting „Helga 6 compact”, our advanced system of clothes distribution and collection. It consists of the management software, a distributing vending machine and an independent collecting machine for used work clothing, the so called-chute. Helga 6 compact has 216 locations for clean clothes; each of them is 7 cm x 27 cm. There is also a video camera which is recording the moment of returning with the view to preventing any abuse and making the operation more secure. The chute has its own computer and it is independent of the distributing machine; therefore, it could be placed anywhere. There is option to install inside a germicidal ultraviolet lamp.

Professional clothes flow management software

Helga 6c system distributes clothes and collect them after they have been used; the whole process is totally automatic and it does not need any extra worker attendance. Thanks to our system you have permanent access to important information, such as: at which stage the clothing is at the moment, the exact number of ready to take clothes in the customer’s place, how many pieces of clothes are circulating at the moment, how many are in use, and how many are waiting for the pickup. Thanks to that information we are able to optimize the use of our resources and also adapt the quantity of clothes to our logistic capabilities. During the returns the user has a chance to notify damage; in such a situation the laundry is being informed about the service needs, it gets immediate information about the specific items of clothing and the type of required repair. That solution is real time saver, since laundry workers do not have to check every item of clothing all the time, and they can prepare themselves for the repair. It makes the information flow better and it make the user more satisfied with the laundry service. The remote control gives an opportunity to control and optimize the whole process of laundry circulation.

- The inspection of each item of clothing at each stage

- Access to clothes 24/7

- You can distribute them everywhere

- Significantly fewer cases of theft and loss

- Clothes damage notification system

- Unit or packaging distribution

- Decrease in consumption

- Supervision and control of whole flow (taken and returned items as well as the supply)

- Remote control by internet from any site

- Automatic supply management

- Automatic stock control

How does it work?

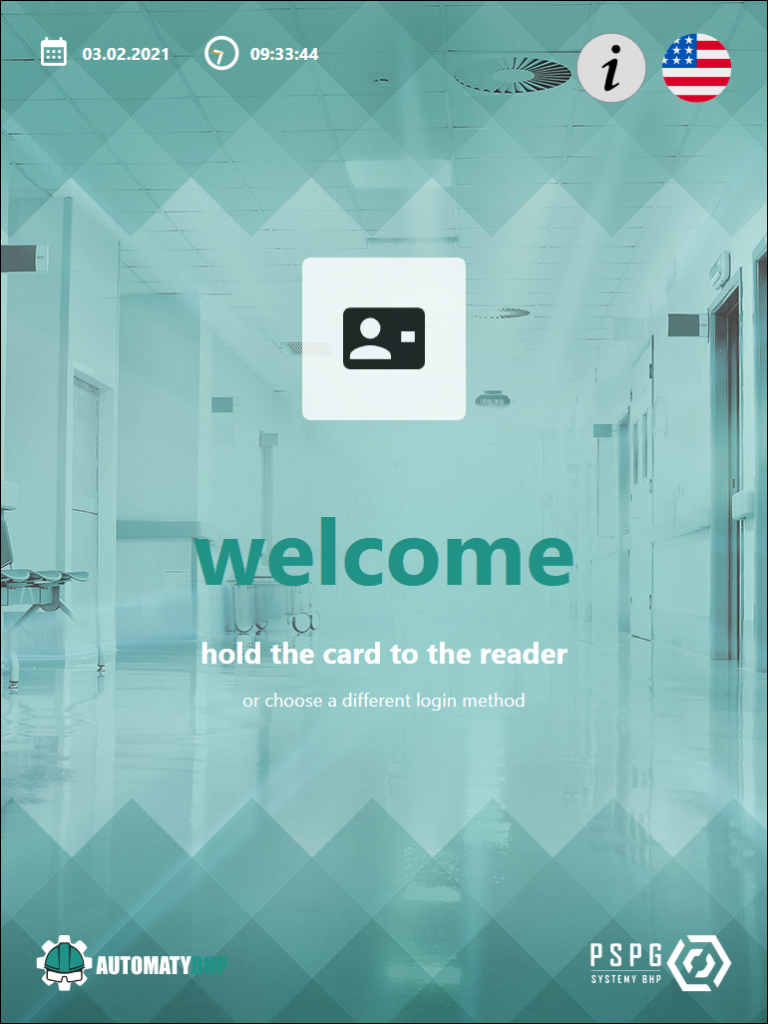

User recognition

The user logs in by sweeping his ID card or by entering his his personal identification number. He gets access to the articles and operations defined for him. The individuals who are not in the database cannot obtain anything from the vending machine.

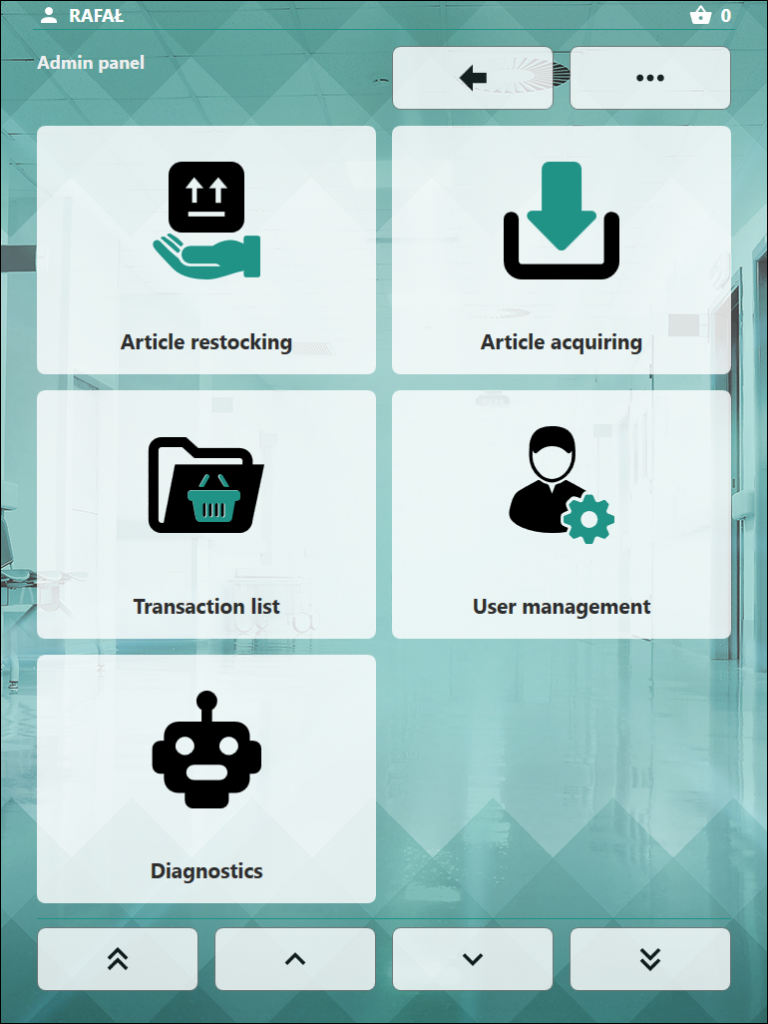

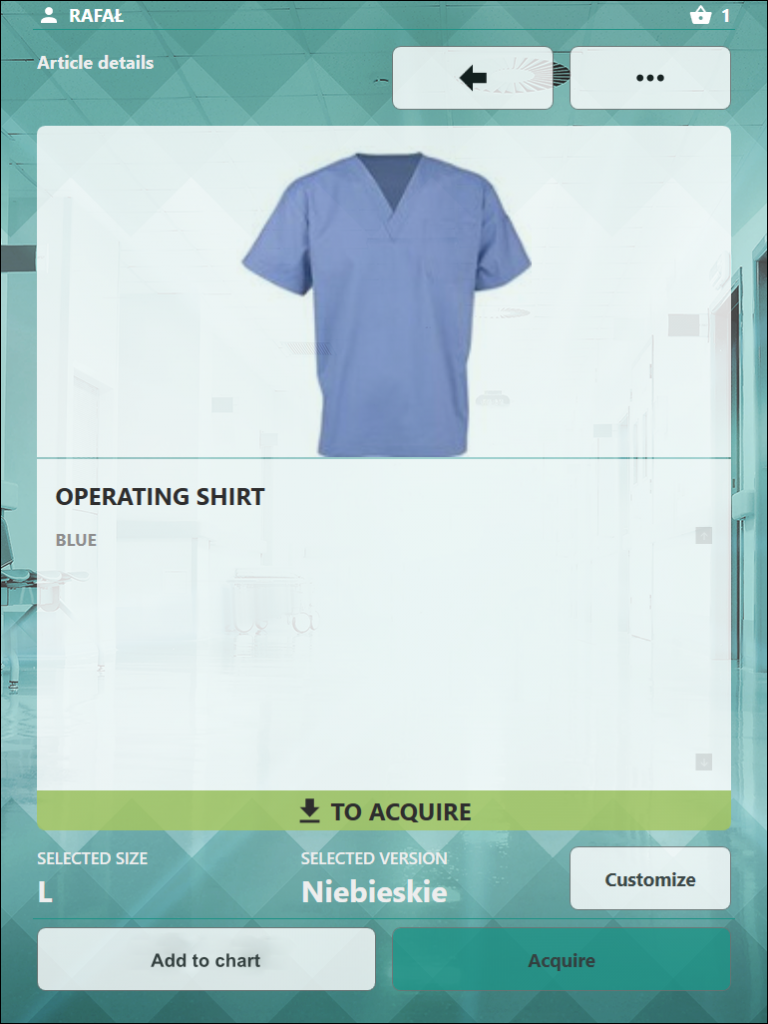

Operation selection

According to the user’s permission, he can choose an option: take, add, return… A regular production worker after sweeping his card over the screen sees a lists of pictures of preselected articles with a short description. He chooses an article, its size (if such information is not in the system) and optionally also a quantity. The required location is opened automatically. The system can display certain information on the screen: the picture of articles, sizes, descriptions, and the stock level.

IT management

Berta distribution and collection system is equipped with a PC which can be accessed only by the system administrator. Optionally it could be equipped with an uninterruptible power supply (UPS) system. Berta has been equipped with a cable, wireless, or mobile Internet connection. Thanks to that we have access to exact data in real time from anywhere in world. Beside the laundry management software, Berta has its own programs which contain three modules.

User interface

User interface is easy to use and user friendly. Our goal was to make the whole process of dispensing articles extremely short and easy. We achieved that goal by creating intuitive interface, displaying big images of articles which can be dispensed. Thanks to that the process of articles searching is simplified. All the operations are performed on a heavy duty, industrial touch screen, ready for hard work in extreme conditions.

Administrator’s interface

The most voluminous part of our system is the administrator’s interface. It offers the possibility of introducing modifications in relation to individuals or whole group of workers defined by occupation, positions or divisions to which they belong. The administrator is able to perform both basic and sophisticated operations, e.g. concerning the databases of: articles; workers; sizes modification, setting the limits of quantity of available articles for workers and groups, etc. The person with the administrator’s license can operate the system from the machine level or from his own computer.

Reports and statistics

The reports module gives access to all system information, such as the history of: taken, returned, added or damaged elements, lists of articles below the minimum availability level articles, already ordered articles etc. It also offers the possibility of creating extraordinary reports.

Washing cycle diagram

English

English  Polski

Polski Français

Français